All facilities are at risk for arc flash, which is the result of a rapid release of energy associated with an electrical current arcing, or jumping an air gap from one conductive surface to another. An arc flash can be initiated by many things including dust, condensation, dropping tools, accidental contact, material failure, and faulty installation. The result can be injuries that are frequently serious and may be fatal. At your facility, you may be responsible for maintaining the electrical equipment and documentation.

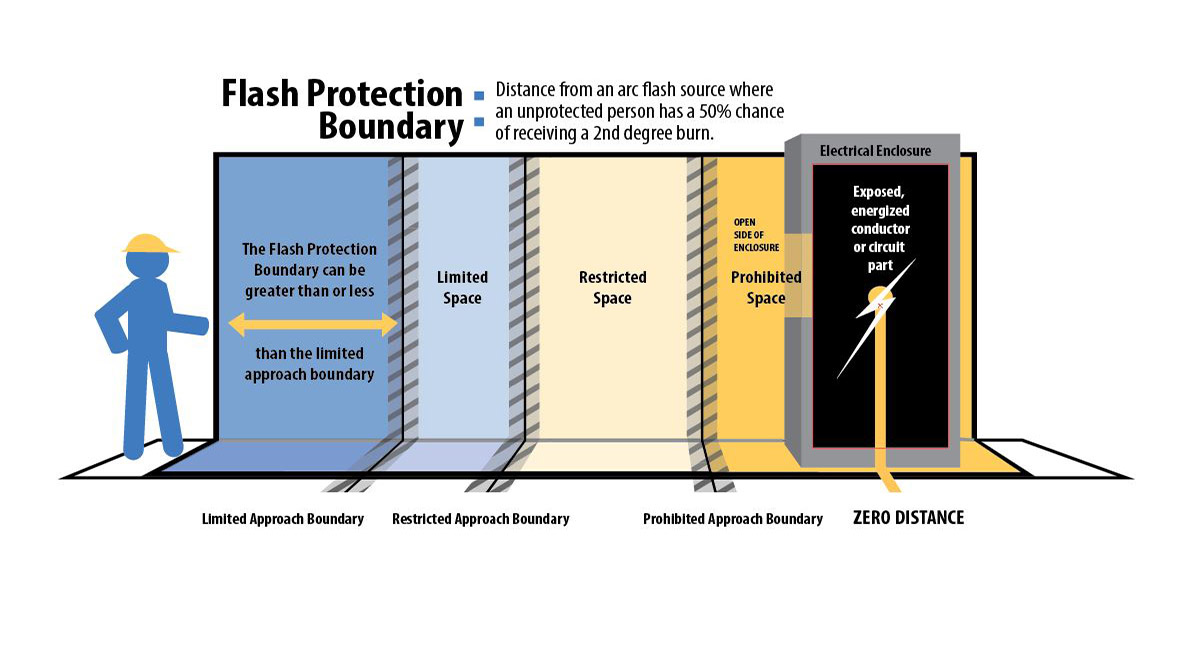

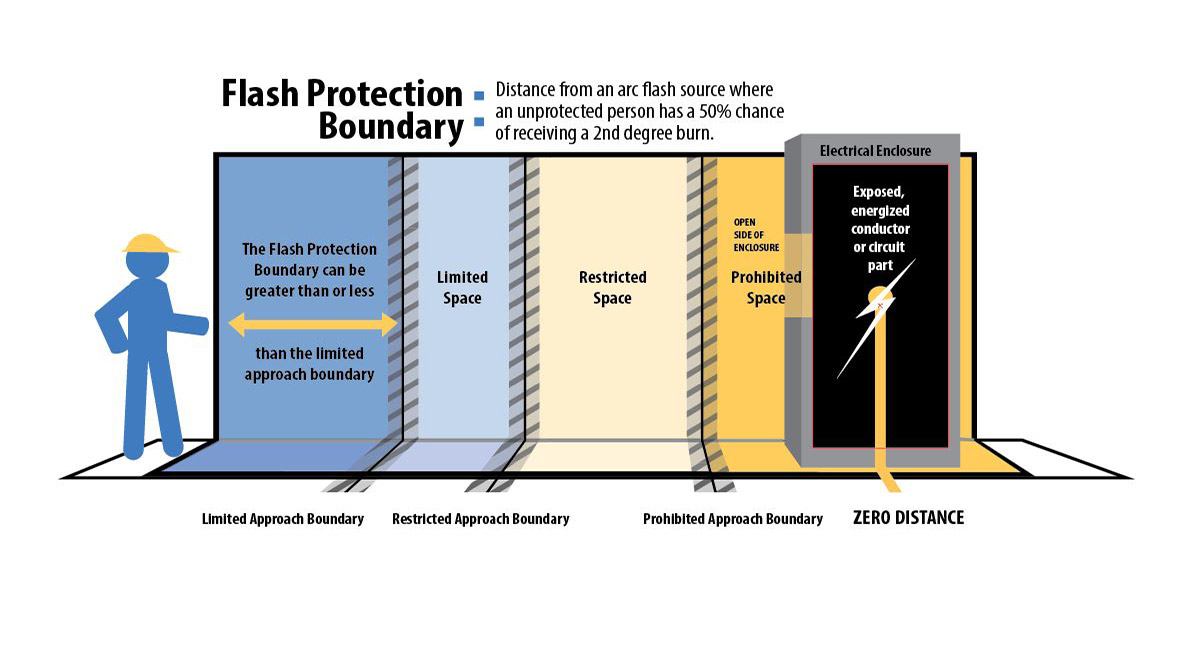

To mitigate risk, it is critical that those involved in the design and ongoing maintenance of electrical distribution systems have an acute understanding of arc flash hazard and the potential magnitude of its consequences. To identify the arc flash hazard at a specific piece of equipment within a given facility, an arc flash study must be performed. As a result of this arc flash analysis, each piece of equipment will be categorized based on the incident energy (level of risk), as well as an associated arc flash protection boundary (an approach limit at a distance from live parts that are uninsulated or exposed within which a person could receive a second degree burn-source: Institute of Electrical and Electronics Engineers. IEEE Std 1584 – 2002).

An Arc flash assessment may enable you to:

- Reduce financial risk and liability exposure

- Reduce the fault clearing time

- Reduce the incident energy level

- Reduce the short-circuit current

- Improve equipment maintenance conditions

- Mitigate ARC flash

Stay in Touch for Monthly Shive-Hattery Industry Insights

More Industrial Projects

Creating the foundations that support community growth.

We're Learning, Growing + Sharing

Stay on top of the latest industry trends as we share how we are staying ahead of them.

Bringing A Massive Amazon Fulfillment Center To Bondurant In Under 12 Months

Commercial

Three Investments to Attract and Retain Employees in the Industrial Market

Industrial

Making the Case for Air Dispersion Modeling

Pre K-12