A client was tasked with creating an action plan for his hospital to support an increase in coronavirus patients. Was there a way to modify or control the existing HVAC equipment to provide a negative pressure area within the hospital?

We’ll share a case study detailing how our hospital client created negative space to quickly and safely manage a COVID-19 surge.

The Existing HVAC Equipment

A portion of the patient rooms are served by a roof mounted air handling unit with heating water and chilled water coils. The distribution system includes variable air volume boxes (VAV) with terminal heating coils. The air handler delivers 55 degrees Fahrenheit air to the VAV boxes which modulate to maintain cooling setpoint or reheat the air to maintain heating setpoint. The minimum airflow to the patient rooms provide six air changes per hour to meet ASHRAE 170, standards for health care facility ventilation.

Conditions to Operate at One Hundred Percent Outside Air

Many air handling units in the Midwest are capable of 100 percent outside air when the outdoor temperature and humidity fall between a certain range, usually 55 degrees Fahrenheit and 30 percent to 50 percent relative humidity.

In the Midwest where the hospital client is located, common temperatures are minus 10 degrees Fahrenheit in the winter and 95 degrees Fahrenheit in the summer.

Could the hospital’s air handler operate at 100 percent outside air at other outdoor conditions?

Analyzing the Air Handling Unit

An analysis was required to determine:

- Existing air handler capability

- Temperatures and relative humidity the unit can go to at 100 percent outside air

- Control strategies to accomplish the task

Air handling units are designed with a certain percent of outside air at extreme design temperatures and usually include a safety factor.

The analysis of the hospital client’s existing air handler showed it was capable of 33 percent outside air at these extreme conditions:

- Chilled water coil analysis: The unit can operate at 100 percent outside air up to 82 degrees Fahrenheit and 50 percent relative humidity.

- Heating coil analysis: The unit can operate at 100 percent outside air down to 32 degrees Fahrenheit. We recommend operating the unit down to 35 degrees Fahrenheit as a safety factor.

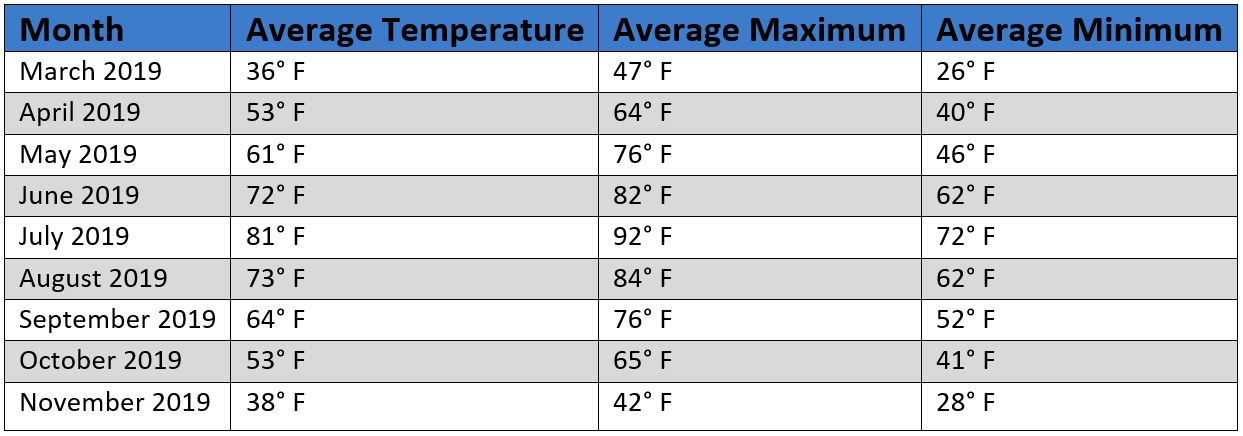

The analysis was conducted measuring outside air temperatures from March 2019 to November 2019 at the client’s location:

As shown above, there are many times the unit can operate at 100 percent outside air.

Control Strategies for Client’s Existing HVAC Equipment to Operate at 100 Percent Outside Air

The following control strategies were customized for the client’s existing HVAC equipment to provide a negative pressure area within the hospital to accommodate a COVID-10 surge:

- Setting all VAV boxes in patient rooms to minimum constant airflow for six air changes per hour. This minimum airflow is enough for temperature control when outside air temperatures are between 35 degrees Fahrenheit and 82 degrees Fahrenheit.

- Closing the return air damper in the air handler to enable 100 percent outside air.

- The supply fan will continue to run based on static pressure set point as usual.

- The return fan (now at 100 percent exhaust) tracks the supply fan with an increase of airflow of 15 percent over that of the supply fan. This 15 percent offset is a starting point and is adjustable. The actual offset should be tested to ensure patient rooms are negative with respect to the corridor by at least 0.01 iwg (inches of water gauge).

- During the Spring or Fall if discharge air temperature begins to rise or drop, the sequence is to slowly open the air handler’s return damper to maintain discharge air temperature. This will still maintain a large amount of outside air and patient rooms will remain negative with respect to the corridor.

Additional Control Strategies to Enable Year-Round 100 Percent Outside Air

If you are considering moving to 100 percent outside air, there are two strategies that can be done to your existing air handlers:

Strategy 1: Add supplemental heating and cooling to the outside air

- If the boiler has capacity and there is enough space in the air handler or outside air duct, add a pre-heating water coil.

- Add an electric pre-heating coil to the air handler or outside air duct.

- If the chiller has capacity and there is enough room in the air handler or outside air duct, add a chilled water coil.

- Add a split system DX coil to the air handler or outside air duct.

Strategy 2: Replace the existing coils with 100 percent outside air coils

- Verify boiler and chiller capacity

HEPA Filter Fan Units: A CDC Approved Option

Another option for a quick negative pressure room is to purchase portable HEPA filter fan units. These units can be installed in the room you would like to make negative and are approved for use by the CDC.

They come with flexible exhaust ducts that can be routed to the:

- Corridor

- Return grille in the room

- Outside (although an exterior wall penetration is required for this installation).

Units typically cost $3,500.

Pro Tip: Start with an Analysis of Your Existing HVAC System

The ability to modify and control your existing HVAC equipment to create negative pressure is dependent upon each individual system. Working with a qualified mechanical engineer can help you perform the analysis and create a strategy that works for your facility.