Incorporating Shock Pads – A Best Practice for Synthetic Fields

As bands march and athletes run on their schools’ athletic fields year after year, the synthetic turf will unavoidably breakdown.

As bands march and athletes run on their schools’ athletic fields year after year, the synthetic turf will unavoidably breakdown.

As bands march and athletes run across their schools’ athletic fields year after year, the synthetic turf will unavoidably breakdown. This reduces its overall ability to absorb impact and can ultimately lead to an increased risk of injury for all who use it.

If you are considering replacing your school’s playing field or making the switch to a synthetic surface, incorporating a shock pad to your field will provide a more absorbent playing surface and can extend the life of the field.

Shock Pad Benefits

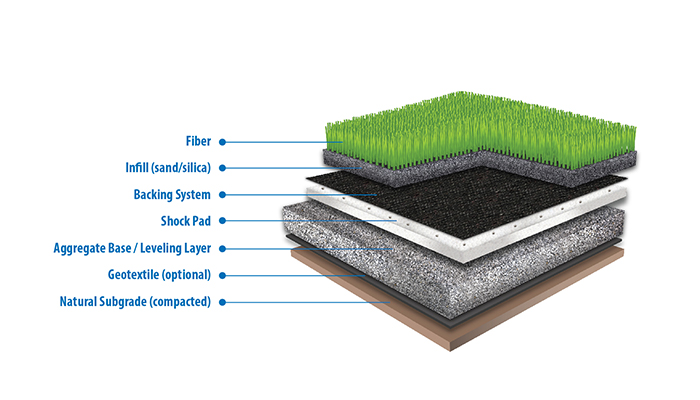

Shock pads come in a range of materials that are bound together with a strong adhesive and absorb impact to varying degrees. As part of an interlocking system, shock pads typically come in small, puzzle-like pieces that hold the system in place and streamline the installation process. The pad is placed beneath the synthetic turf and serves as a supplemental barrier between the player and the ground beneath.

Shock pads provide a number of benefits including:

Reducing Maintenance. Infill within the turf will migrate over time due to its lack of density as well as the inconsistency of where the actions take place on the field; this requires routine grooming and maintenance to evenly distribute the infill around the field. The inclusion of a pad can potentially allow for a turf system that uses less infill. In turn, this reduces the amount being displaced and lowers the maintenance needed to keep the field in suitable playing condition.

Increasing Shock Absorption – GMax is a widely used measurement of a surface’s shock-absorbing properties, emulating how much force a player feels when coming in contact with the ground. A properly installed synthetic turf field will have a GMax value somewhere between 80 and 90. A higher GMax value indicates a harder field meaning it is less likely to absorb impact.

Because GMax will naturally increase over time (i.e. your field will naturally become harder), incorporating shock pads with your synthetic field is one method to help decrease GMax and improve shock absorption.

Extending the Field Life – According to the American Society of Testing and Materials (ASTM), a field with a GMax above 200 is considered out of compliance and is required to be replaced. Synthetic turf companies will typically offer a warranty that assures the field will remain in compliance for up to eight years. Incorporating a shock pad can extend this lifespan and provide greater certainty that the field is safe to play on.

As a best practice, it is highly recommended to regularly conduct field impact testing to document the performance of your field over its lifespan. It is especially beneficial if you are considering the inclusion of a shock pad into your next synthetic field.

Shock pads play a major factor in improving the level of safety you want to achieve for your field.

Testing for GMax before and after the shock pad is installed will provide additional supporting evidence of its benefits.

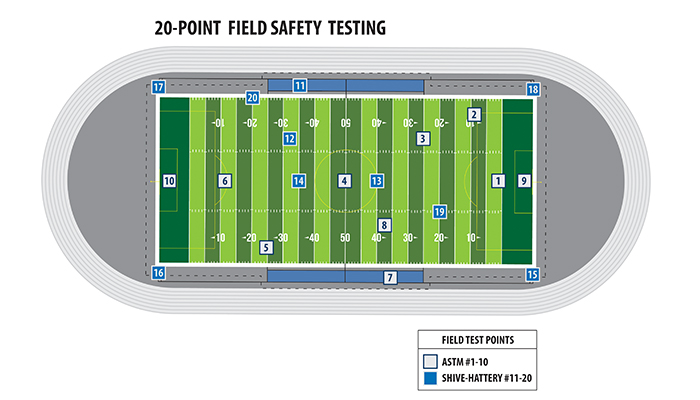

When field impact testing occurs, ASTM standards require 10 specific locations to be examined. Shive-Hattery tests additional locations across the field and evaluates other safety measures such as infill height, surface temperature and wear patterns to provide a more thorough assessment. These are all valuable factors to consider when gauging your field’s overall condition.

Beyond benchmarking for shock pads, here are few more reasons for field impact testing: