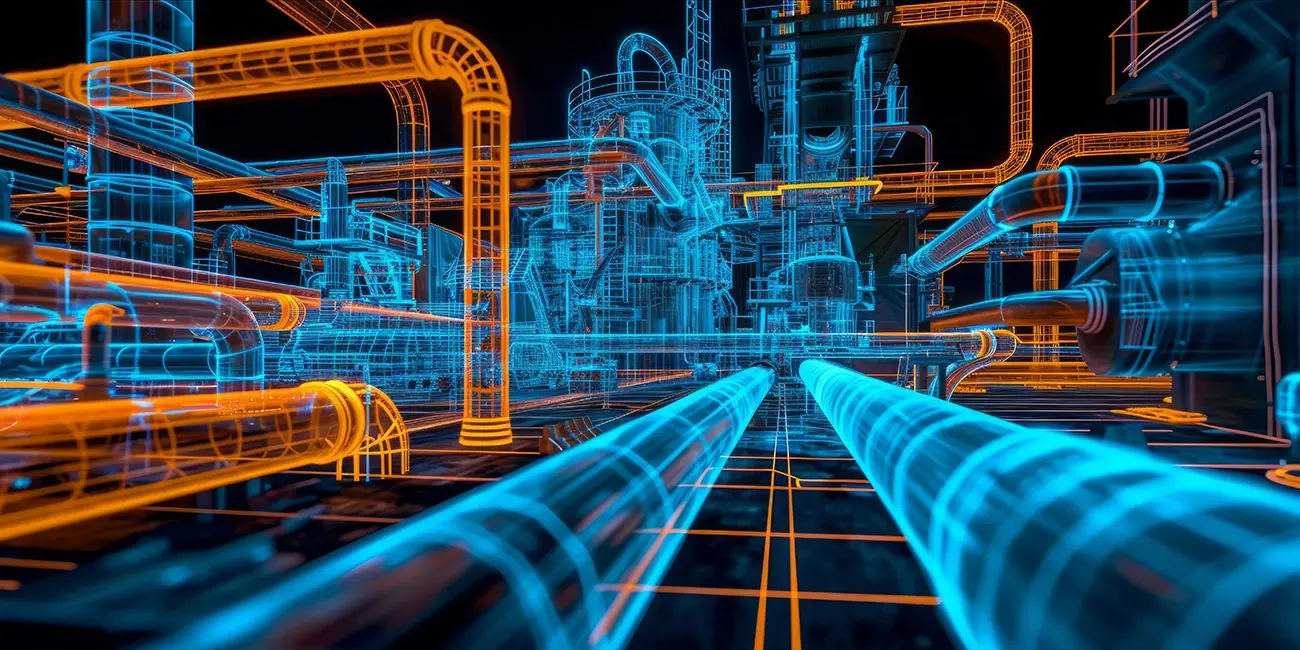

Model the future before you build it.

At Shive-Hattery, Process Design is about precision, foresight, and collaboration. We help clients visualize their space’s capabilities and constraints long before equipment is purchased or construction begins. With advanced modeling, immersive coordination tools, and real-world scanning, we ensure your process fits, both literally and strategically.

Why Process Design Matters

- No room for error? No problem. Our 3D models are accurate down to 1/16 of an inch. Whether you’re integrating new equipment into a maze of existing piping or replacing obsolete systems, we help you avoid costly surprises.

- Missing Documentation? We Recreate It. Many industrial systems were built decades ago, and original drawings are long gone. We scan, model, and document your space so you can move forward with confidence.

- Custom Equipment? We Model It. From tanks to conveyors, we convert any cutsheet into a 3D model tailored to your exact specifications. Our team uses Inventor, Plant 3D, Navisworks, and ReCap to create fabrication-ready deliverables.

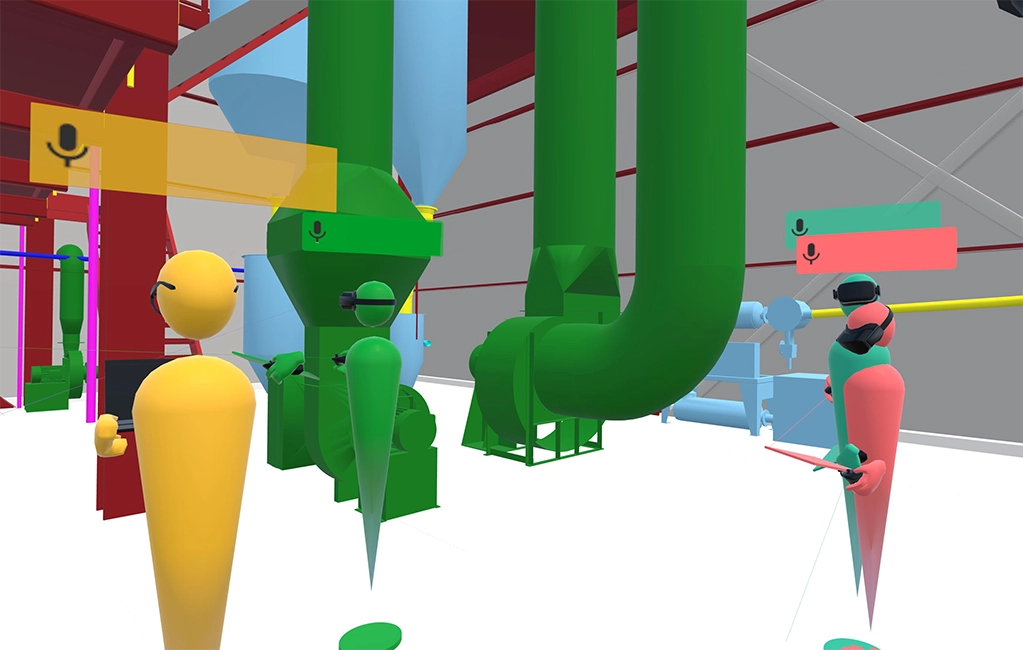

- Stakeholder Alignment? We Make It Easy. Take your team on a virtual reality tour of your future facility. Meet inside your 3D-modeled space to review options, resolve conflicts, and keep everyone on the same page.

Our Capabilities

- Process Design Services

- Equipment modeling and layout

- P&ID and PFD assistance

- Walk-down as-built documentation

- Red-line markups

- Expansion forecasting

- Bill of Materials (BOM) generation

- Isometric and orthographic drawings

- Pipe Design

- Sanitary/hygienic, utility, and wastewater piping

- Incorporation of existing specs

- Pipe stress analysis for safety and reliability

- Design Coordination

- 3D scanning (terrestrial and drone)

- Clash detection

- Mixed reality reviews

- Model reviews throughout the project lifecycle

- Visualization Tools

- Revit, Inventor, Plant 3D, Navisworks, ReCap

- Matterport, Twinmotion, Enscape

- VR headsets (Oculus Quest, HoloLens 2, Magic Leap)

- Block-based component views for system clarity

Digital Twin + Mixed Reality

We leverage extended reality and visualization tools to involve all stakeholders, track issues remotely, and predict performance through digital twins. These dynamic, real-time replicas of physical systems enable predictive maintenance, asset tracking, and performance simulation. Mixed reality tools allow you to verify designs in the field before construction begins, reducing risk and improving outcomes.

Real-World Results

From food processing plants to packaging facilities, our Process Group has helped clients modernize operations with minimal downtime. Recent projects include:

- Confidential Meat Processing Client

- Phased demolition and installation drawings minimized downtime while upgrading critical processing equipment.

- Kirkwood Community College

- Training and innovation in action; immersive technology for real-world learning.

- Precision Spool Fabrication

- Precision spool fabrication modeled for seamless installation and reduced field errors.

Integrated 3D Scanning

We use high-definition laser scanning and drone technology to capture millions of data points and generate photorealistic point clouds. These models are imported into Revit, Navisworks, and other platforms to validate designs and identify conflicts before materials arrive on site.

Let’s Design What’s Next

Whether you’re updating a legacy line or building a new cleanroom, our Process Design team is ready to help you see and shape the future.

For immediate assistance, contact us at 800.798.0313 or by email.

Coordinate Measure Machine (CMM) Rooms

Industrial

ALKAR-RapidPak Manufacturing Study

Industrial | Lodi, WI

Blackmer Pumps – Factory and Office Addition and Renovation

Industrial | Grand Rapids, MI

Building Addition

Industrial | Horicon, WI

Data Centers

Stay in Touch for Monthly Shive-Hattery Industry Insights

More Industrial Projects

Creating the foundations that support community growth.

We're Learning, Growing + Sharing

Stay on top of the latest industry trends as we share how we are staying ahead of them.

Quick Wins for Manufacturing Facilities

Industrial

Capriana Homes Wins Development of the Year at CRE Summit

Commercial

Jen Bennett Highlights Iowa’s Growth and the Rise of the Quad Cities

Commercial